In the business world, safety holds a paramount position, especially when dealing with hazardous materials like explosives. These materials are crucial in various sectors, from mining to construction, but mishandling can lead to severe consequences.

This article by Ludus provides an overview of the risks associated with explosive materials and how to implement effective training for involved employees.

What is Explosive Material?

Explosive material refers to substances that, under certain conditions, can release energy suddenly and violently in the form of explosions.

These materials vary in composition and uses, including chemicals and industrial explosives used in construction. Due to their volatile nature, it is imperative to understand their properties and learn how to handle them properly.

Risks Associated with Explosive Material

Improper handling of explosive materials can have tragic consequences, including severe injuries, property damage, and loss of lives.

Risks include explosions, fires, release of toxic substances, among others. These hazards not only affect directly involved workers but also pose a risk to the entire company and its surroundings.

Let's explore common explosion hazards according to NFCC:

- Primary Blast Injuries: Direct effects of a shockwave on the body, such as eardrum rupture and pulmonary hemorrhage.

- Damage to Surrounding Materials: Explosives can cause damage to surrounding materials like bells, glass, windows, etc.

- Structural Collapse: Risk of entrapment after a structure collapses.

- Generation of Toxic Gases: Explosives can generate toxic gases.

- Noise: Loud and sudden noises can cause hearing damage.

- Fires.

Training in Explosive Material Handling

Solid training is the foundation to ensure safety in handling explosive materials.

Employees must understand the properties of the materials they handle and the proper procedures for storage, transportation, and usage. This includes identifying potential risks and adopting preventive measures.

Training with Virtual Reality

Technology is revolutionizing safety training.

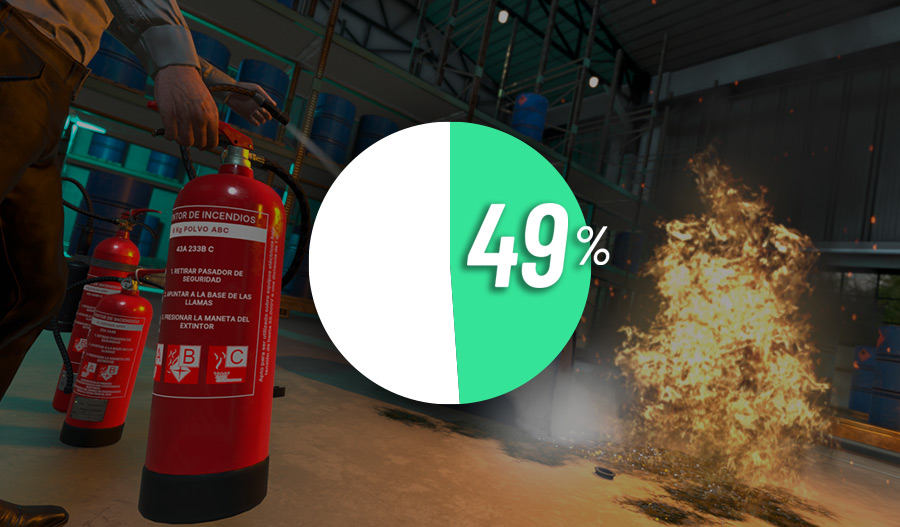

Virtual Reality (VR) has become a valuable tool for simulating real situations in the handling of explosive materials in a safe and controlled environment. Through immersive simulations, employees can practice skills and make decisions in controlled risk scenarios without putting themselves in danger.

Signaling for Explosive Materials

Proper signaling is vital to prevent accidents.

Standardized labels, colors, and symbols should be used to identify and distinguish explosive materials. This ensures that everyone in the workplace recognizes and respects the presence of these materials, reducing the likelihood of incidents.

Safety and Prevention Protocols

Safety protocols must be clear, effectively communicated, and rigorously enforced.

These protocols should cover everything from handling and storing explosive materials to using appropriate personal protective equipment. Additionally, emergency response procedures should be established to act quickly in case of incidents.

It is highly recommended to train staff in firefighting, which often goes hand in hand with accidents involving explosive materials.

Conclusions

Safety in handling explosive material is a responsibility that cannot be underestimated.

Proper training is essential to ensure the safety of employees, the integrity of the company, and the protection of the environment. Combining traditional training with virtual reality-based occupational risk prevention training can enhance the effectiveness of training programs.

Remember that investing in safety is an investment in the long-term success of the company and the protection of its members.